Compressive test hydraulic press

Hydraulic press for compressive tests on cubic and cylindrical specimens. There are also available attachments for indirect tensile test and 4 point loading tests. The press can accommodate various heights of specimens since it has detachable spacer plates. The load is imposed in a Force/Time control manner by means of a hydraulic transducer.

Capacity: 2000kN.

Mixing and Casting equipment

Equipment for mixing and casting of concrete in the laboratory:

- 45L Mixer

- 60L Mixer

- 65L Pan Mixer

- Vibrating Table

- External Vibrator

- Standardized tamping rods

Buckets, Containers, Volumetric Beakers, Scoops, Trowels and other expendable materials on demand.

Standard formwork for specimens

Standardized specimens formwork for concrete consisting of 20 polymer 15cm cube moulds, 10 polymer 15*30cm cylindrical moulds, 5 cast iron 15cm cube moulds, 3 stainless steel 15*15*50cm prism moulds and an aluminum mould arrangement for 10*10*10cm cubes or 10*10*40cm prisms. Customized formwork can be achieved with various materials such as metal or wood fair face moulds provided in the laboratory.

Mortar and Cement Paste testing.Automatic Compression Machine

Testing of standard mortar specimens. Compressive tests on 40mm cubes and 40*40*160mm prisms. Comes with attachments for 3 point loading, compression plates. Can also accommodate specimens of up to 200mm height for customized tests according to the needs.

Automatic Vicat Aparatus

Evaluation of standard cement paste and determination of the initial setting time of cement without continuous attendance on the specimen. Total duration and penetration results report printed by onboard dot matrix.

Jolting table for cement paste mould casting

5 gang moulds of 3 prisms each (40*40*160mm) also provided

Vicat Aparatus

Evaluation of standard cement paste and determination of the initial/final setting time of cement

Cement/mortar mixer

Electric flow meter

Determination of flow properties for cement paste/mortar fresh specimens.

Slump test

Fresh concrete workability test

Manual and electric air entrainment meter

Metal volumetric containers (5)

J – Ring

Self compacting concrete workability/flow test

Metallic marked concrete flow surface

Used for tests such as J ring, V funnel and as a general impermeable surface

“V” Funnel

Self compacting concrete workability/flow test.

“L” Channel

Self compacting concrete workability/flow test

“U” Channel

Self compacting concrete workability/flow test

Spreading table cone and surface

Fresh concrete workability/flow test

Curing of specimens

Curing tank with water heater and thermostat.

2 simple water curing tanks

2 climate chambers capable of cyclic conditions.

Concrete specimens density determination tank

Heater for capping compound on specimen

Electric disk for stone/concrete specimen cutting

RC nondestructive testing and reinforcement testing facility

Salt spray chambers

Chambers capable of providing pressurized fogging of salt mixtures to induce accelerated corrosion on various types of specimens such as rebars and RC prisms.

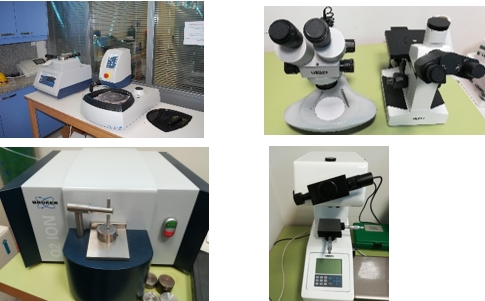

Metallography equipment

For determining rebar damage.

Surface polishing machine

Precision cutting machine

Zoom stereo microscope

Metallurgical microscope

Micro-Vickers Hardness tester

Emissionspectrometer

Nondestructive RC testing

Rebar detector (Half cell potential)

Corrosion mapping instrument

Permeability test instrument

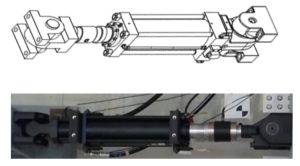

Tensile testing machine

Tensile testing machine with displacement control option. It receives jaw grips for reinforcement, sheets or plates. It can also apply compression and receive different grips for flexural or compressive tests. Capacity 150kN.

Fatigue testing machine

Hydraulic water cooled tensile/compressive machine capable of being operated for extended time periods and for large numbers of cyclic load repetitions. It can also apply static loads, suitable for tensile, compressive and flexural tests. It comes with a dedicated Data Acquisition Chassis, clip gauges, LVDTs and customable command software for a vast variety of test control options.

Capacity: 250kN

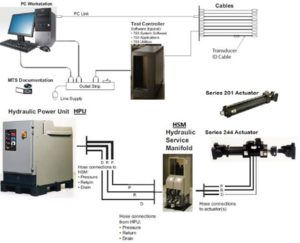

Large Structures / Seismic Facility

Strong floor – strong wall facility for static and pseudo-dynamic tests on real scale structures. The arrangement has a total strong floor area of 88.5m2 and a 5*5.75*1m strong wall. An overhead 10T crane covers the whole area. The forces are applied on structures by servo-hydraulic actuators, connected on a controller network for operation and powered by a hydraulic power unit and hydraulic service manifolds. There two dynamic double-ended and two single-ended actuators. They can be adjusted and programmed in any combination of simultaneous or independent operation. The controller system provides analog and digital outputs to extract data on external acquisition systems.

MTS Hydraulic Power Unit

Hydraulic water cooled pump designed for output pressure of 3000psi. The pressure fluid is branched through manifolds to 4 actuators.

MTS Hydraulic Service Manifold

Hydraulic water cooled pump designed for output pressure of 3000psi. The pressure fluid is branched through manifolds to 4 actuators.

MTS FlexTest 60 Controller

Provides real-time closed-loop control and function generation to drive the actuators. Receives the measurements of the actuators sensors (LVDT, Load Cells, Temposonic) and gives readouts.

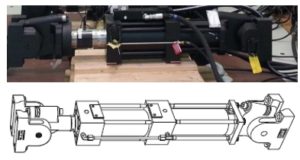

MTS series 244 actuators

Two double-ended (equal tension/compression), double-action (can extend and retract) hydraulic actuators with dynamic action rating and swivel base at both ends.

Stroke: ±125mm

Capacity: 500kN.

MTS series 201 actuators

Two single-ended, double-action hydraulic actuators with swivel base on both ends. Stroke: ±250mm, Capacity: 500kN Compression/250kN Tension